PLC Programming in 2025: What’s New and What Matters

Introduction

Programmable Logic Controllers (PLCs) have been the backbone of industrial automation for decades. But in 2025, the world of PLC programming is evolving faster than ever. With the rise of IoT, AI, cloud computing, and smarter design tools, PLCs are more powerful—and more essential—than ever before.

Let’s explore the biggest trends and innovations shaping PLC programming today.

1. IoT and IIoT Integration

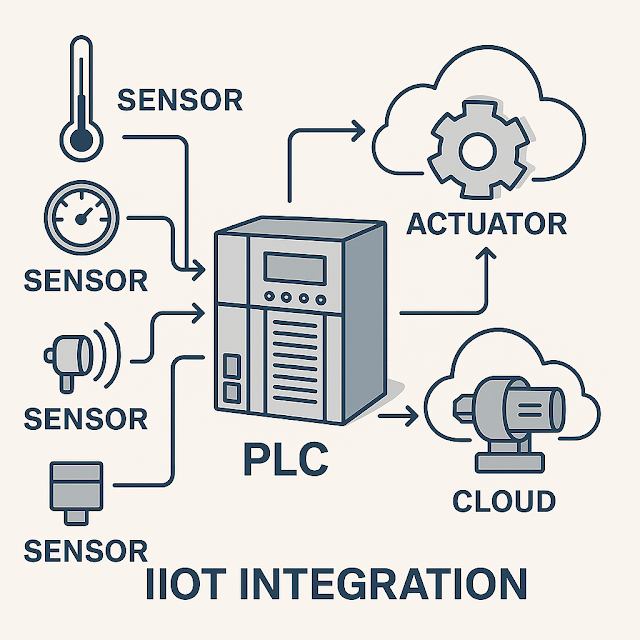

Modern PLCs are no longer isolated. Thanks to the Industrial Internet of Things (IIoT), PLCs now connect seamlessly with sensors, devices, and cloud platforms. This enables real-time data exchange, remote monitoring, and predictive maintenance, making factories smarter and more responsive.

2. AI and Machine Learning in PLCs

Artificial Intelligence (AI) is revolutionizing Programmable Logic Controller (PLC) programming. AI-driven PLCs can analyze data, optimize processes, and predict equipment failures before they happen. This means less downtime, improved efficiency, and smarter automation.

- Predictive Maintenance: AI algorithms monitor equipment health and schedule maintenance only when needed.

- Process Optimization: Machine learning enables PLCs to adjust parameters in real-time for maximum efficiency.

3. Cloud-Connected PLCs

Cloud technology allows PLCs to be managed and monitored from anywhere in the world. Cloud-capable PLCs store and process data off-site, making collaboration and scalability easier than ever. This is especially useful for multi-site operations and remote troubleshooting.

Benefit: Reduced on-site hardware, easier data sharing, and improved system flexibility.

4. Enhanced Security

The rise in connectivity brings new cybersecurity challenges. Modern PLCs now feature robust encryption, authentication, and regular updates to protect against cyber threats.

Security is no longer optional—it’s essential.

5. User-Friendly Interfaces and Advanced Languages

While ladder logic remains popular, modern PLCs are embracing advanced languages like Structured Text (ST) and Function Block Diagram (FBD) for complex tasks. At the same time, programming environments are becoming more graphical and intuitive, lowering the barrier for new engineers.

6. Edge Computing and Digital Twins

Edge computing brings data processing closer to the machine, right inside the PLC. This means faster decision-making and lower network congestion. Digital twins (virtual models of real processes) allow engineers to test and optimize systems before deploying changes to the factory floor.

The future of PLC programming is dynamic and promising:

- Smarter with AI and machine learning

- More connected through IoT and cloud

- More secure with advanced cybersecurity

- Easier to use with modern interfaces and languages

- If you want to stay competitive in industrial automation, now is the time to embrace these trends.

What PLC innovation excites you most? Share your thoughts in the comments below!

Hi, please leave a comment.