Error and Alarm Handling in PLC Programming: A Practical Guide

Introduction

Handling errors and alarms well is crucial for safe and reliable automation. If alarms are not managed properly, operators can get overwhelmed, miss important warnings, or even cause safety incidents. This guide explains the main ideas and techniques for setting up alarms and faults in PLC programs, using industry best practices and real-world logic examples.

What Makes a Good Alarm?

- An alarm should only exist if it needs an operator to act.

- Alarms are not for information only—they should signal something abnormal that requires attention.

- For example, don’t alarm every time a pump stops. Only alarm if the pump is supposed to be running and it isn’t.

Example: Pump Alarm Logic

Example:

|---[Pump Should Run]---[Pump Not Running]---(Pump_Failure_Alarm)---|

This alarm only triggers if the pump fails when it should be running.

Organizing Alarms and Faults in PLC Code

- Keep alarm logic in a separate part of your PLC program.

- Assign each alarm a unique bit or code, often using an array or integer.

- This makes it easier to test, update, and troubleshoot alarms.

Example:

|---[Condition for Alarm 1]---(Alarm_1_Bit)---| |---[Condition for Alarm 2]---(Alarm_2_Bit)---|

Latching and Resetting Alarms

- Alarms should stay ON (latched) until they are acknowledged and reset, even if the fault clears.

- Use a reset action (like an HMI button) to clear the alarm.

- For non-critical warnings, you can allow auto-reset, but always log the event.

Example:

|---[Alarm Condition]---+---(Alarm_Latch)---| | | |---[Alarm Reset]-------+

First-In-Fault and Fault Codes

- When several faults happen, it’s helpful to know which one occurred first.

- Store the code of the first alarm in a register for display and troubleshooting.

- Reset this register when the system is reset.

Example:

|---[Fault 1]---[Fault_Register = 0]---(MOV Fault1_Code, Fault_Register)---| |---[Fault 2]---[Fault_Register = 0]---(MOV Fault2_Code, Fault_Register)---|

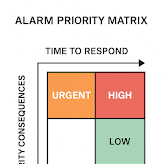

Prioritizing Alarms and Helping Operators

- Not all alarms are equally important. Use three levels: Emergency, High, and Low.

- Show different colors and sounds for each priority on the HMI.

- Group alarms by area or equipment for clarity.

- Every alarm message should tell the operator what happened, what to do, and what might happen if ignored.

Connecting Alarms to HMI/SCADA

- Link alarm bits or codes to HMI/SCADA so operators can see, acknowledge, and reset alarms.

- Show alarm history with timestamps and priorities.

- Use features like alarm shelving (temporary suppression) to avoid overwhelming operators during upsets.

Monitoring and Improving Alarm Systems

- Track key numbers: alarms per day, most frequent alarms, chattering (repeated) alarms, and alarm floods (too many alarms at once).

- Regularly review and improve alarm lists to remove unnecessary or duplicate alarms.

- Keep a master list of alarms with details for training and troubleshooting.

Practical Tips

- Document every alarm: Keep a spreadsheet or database with alarm codes, descriptions, causes, and recommended actions.

- Suppress nuisance alarms: Use timers and logic to avoid alarms during known transitions (like startup).

- Test alarm logic: Simulate faults and check alarm behavior before going live.

- Centralized alarm handling: Use function blocks or routines for easier updates.

- Review regularly: Ensure alarms remain relevant as the process evolves.

Conclusion

Good error and alarm handling make automation safer and easier to manage. By following these simple, proven techniques—clear alarm logic, latching and reset, first-in-fault tracking, prioritization, and strong HMI integration—you help operators focus on what matters and keep your plant running smoothly.

Hi, please leave a comment.